Welcome to Join Mondince Bike - A well-known factory in carbon bike industry since 2007.

What Is Carbon Fiber? The Ultimate Guide to the High-Performance Material

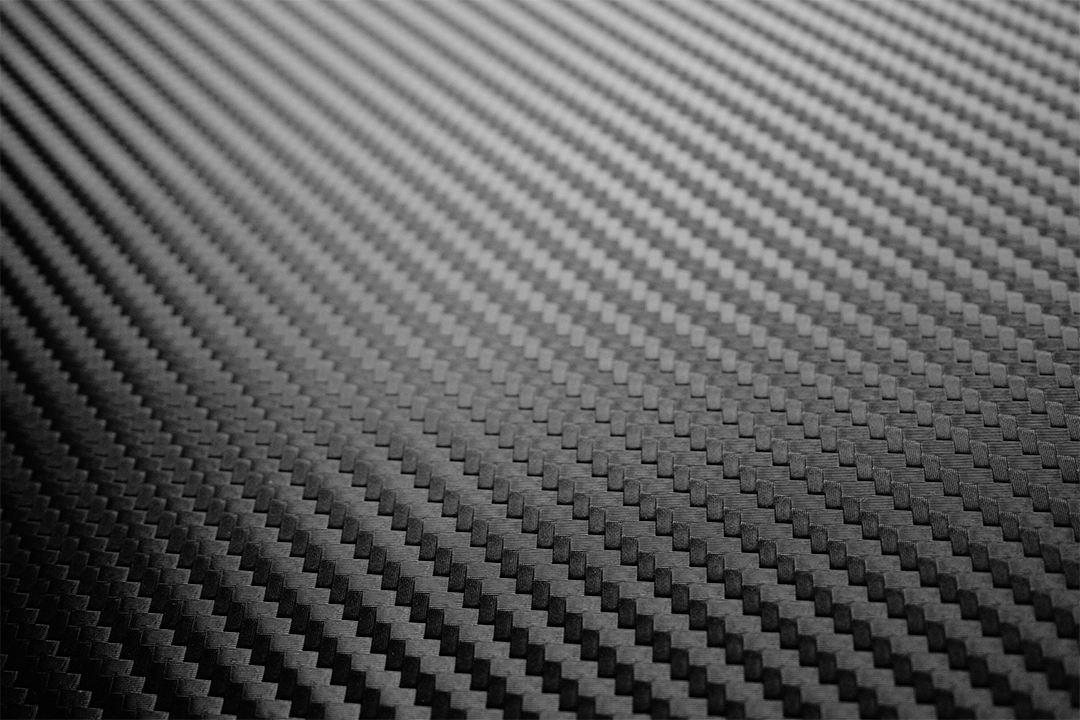

Introduction to Carbon Fiber

Carbon fiber, sometimes referred to as graphite fiber, represents the pinnacle of modern material engineering. This advanced polymer composite combines exceptional strength with remarkable lightness, making it a preferred choice across numerous industries seeking high-performance solutions.

Key Properties and Advantages

Carbon fiber stands out for its impressive characteristics that outperform traditional materials:

-

Superior Strength-to-Weight Ratio: Five times stronger than steel yet significantly lighter

-

Exceptional Stiffness: Twice as rigid as steel while maintaining flexibility in design

-

Chemical Resistance: Highly resistant to corrosion and chemical degradation

-

Temperature Tolerance: Maintains integrity under extreme heat conditions

-

Minimal Thermal Expansion: Stable across varying temperature ranges

These properties make carbon fiber composite materials ideal for applications where weight reduction without compromising strength is critical.

Manufacturing Process: How Carbon Fiber Is Made

The production of high-performance carbon fibers involves a sophisticated chemical and mechanical process:

Precursor Preparation

The journey begins with creating thin, strong crystalline filaments of carbon, each potentially thinner than a human hair. These fundamental carbon fibers reinforcing the composite material are meticulously produced through controlled manufacturing.

Carbonization Process

During this crucial phase, fibers undergo intense heating in an oxygen-free environment to prevent combustion. This process triggers carbonization, where atoms vibrate violently, expelling non-carbon elements and leaving behind tightly interlocked carbon chains.

Production Stages

-

Spinning: Transforming raw materials into fibrous structures

-

Stabilizing: Preparing fibers for high-temperature processing

-

Carbonizing: Converting stabilized fibers into pure carbon form

-

Surface Treating: Enhancing bonding capabilities

-

Sizing: Applying protective coatings for handling and processing

The resulting carbon fiber material can be twisted like yarn, woven into cloth, or molded with resin content optimization to create durable components with a glossy finish.

Advanced Applications and Industry Use

Carbon fiber's unique properties make it invaluable across multiple sectors:

Aerospace Industry

The pursuit of weight reduction in aircraft and spacecraft has made carbon fiber composite materials essential for modern aviation components.

Automotive Excellence

High-performance vehicles utilize carbon fiber components for structural elements, body panels, and interior features, significantly reducing weight while enhancing safety and performance.

Military and Defense

The military sector employs carbon fiber for protective gear, vehicle armor, and specialized equipment where strength and lightness are mission-critical.

Recreational Innovation

From sporting goods to luxury items, carbon fiber provides both functional advantages and aesthetic appeal with its distinctive glossy finish and technological appearance.

Understanding Carbon Fiber Varieties

Dry Carbon Fiber vs. Traditional Options

What is dry carbon fiber? This advanced manufacturing approach involves using pre-impregnated materials that offer superior control over resin content and distribution, resulting in enhanced performance characteristics compared to wet layup methods.

Material Grades and Performance

The carbon fiber production process can yield various grades of material, including high modulus variants designed for specific applications requiring exceptional stiffness and dimensional stability.

Conclusion: The Future of Advanced Materials

Carbon fiber continues to evolve through advancements in carbon fiber production techniques and material science. As manufacturing processes become more refined and accessible, this exceptional material is finding applications in increasingly diverse fields, from renewable energy to architectural design.

The ongoing development of high-performance carbon fibers and innovative composite formulations ensures that carbon fiber will remain at the forefront of material technology, driving innovation across industries that demand the perfect balance of strength, lightness, and durability.

Whether you're considering carbon fiber components for automotive applications, aerospace projects, or consumer products, understanding these fundamental aspects of carbon fiber technology will help you make informed decisions about implementing this advanced material in your next project.